معلومات عنا

حقوق الطبع والنشر © 2024 Desertcart Holdings Limited

⚡ Cut sharper, last longer, and own every project with SPEED TIGER!

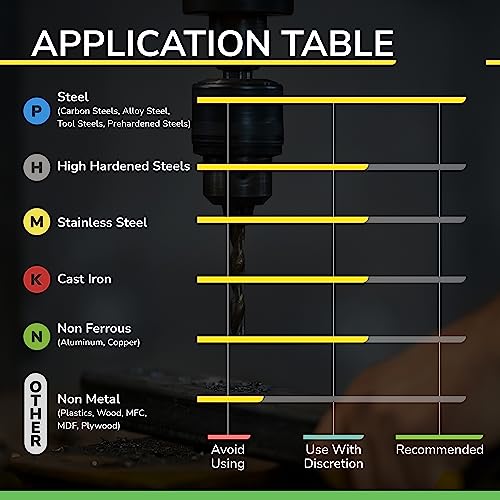

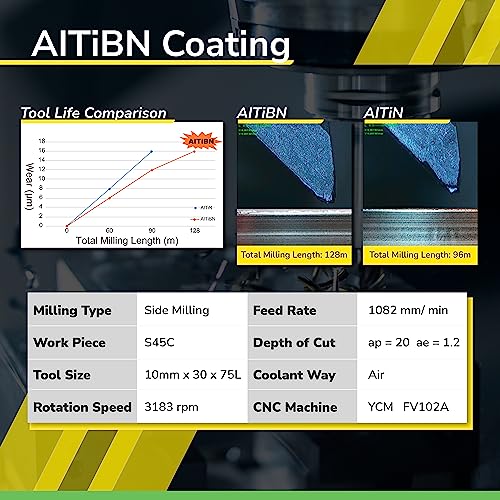

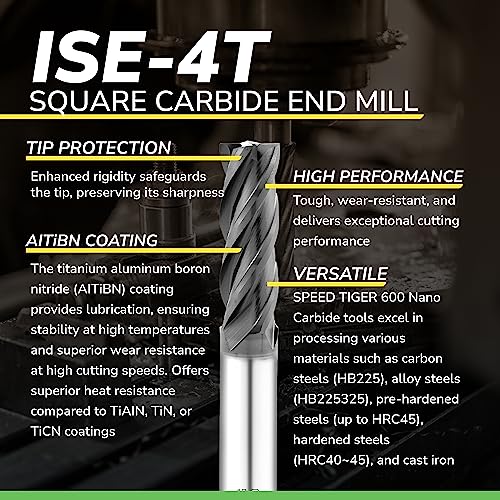

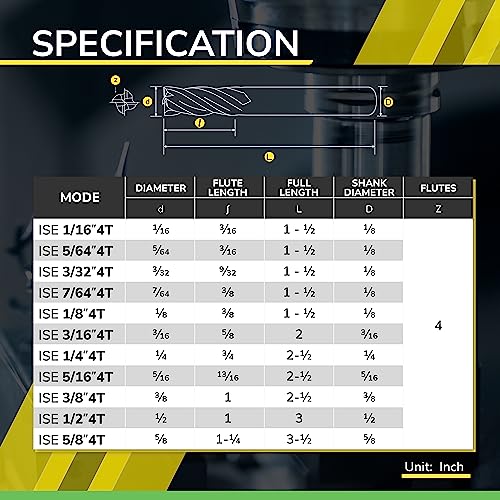

The SPEED TIGER ISE Carbide Square End Mill is a 4-flute, 7/64" precision tool crafted from micrograin carbide and coated with advanced AlTiBN for superior heat resistance. Engineered for machining a wide range of steels—including hardened grades up to HRC69—this end mill delivers professional-grade accuracy (±2μm) and durability, making it the go-to choice for demanding manufacturing and DIY projects. Comes in a 5-piece set with dedicated customer support to ensure peak performance.

| ASIN | B07FSBH8S1 |

| Are batteries included? | No |

| Brand | SPEED TIGER |

| Country of Origin | USA |

| Customer Reviews | 4.5 4.5 out of 5 stars (993) |

| Cut Type | Finishing |

| Cutting Diameter | 7/64" Inches |

| Date First Available | 10 December 2018 |

| End Cut Type | Square End |

| Finish Type | AlTiN |

| Item Weight | 41 g |

| Item model number | ISE7-64-4T |

| Manufacturer | SPEED TIGER |

| Material | Carbide |

| Model number | ISE7-64-4T |

| Number of Cutting Edges | 4 |

| Number of Flutes | 4 |

| Product Dimensions | 38L x 3W Millimeters |

| Shape | Square |

| Size | 7/64 in |

| Tolerance Held | Precision |

A**R

They appear to be well made-super sharp. Their performance is tops.

P**S

Used it to cut a 1/2" keyway into a shaft 7" long. worked with great satisfaction

B**N

These are some of the best carbide cutters I have ever used

B**N

Bought these for a hobby. Received them and like that they are packaged individually, thus helping keep them sharp. Used them on a firearm building project and only eneded up using one. But stayed sharp and met the needs of what I was using it for. If your are a hobbyist and looking for some high quality milling bits with out having to pay a premium these are the ones to go to.

B**.

I use speed tiger endmills on my Bridgeport every day. They are verysharp and stay sharp for a long time. cut gummy 1018 steel like butter dry. sharp enough to cut aluminum. Work great on stainless and tool steel. Surface finish on facing is always close to mirror. edge is fine for machine parts but would need to polish for ornate parts. If you are breaking these things. Lock the x when cutting x and lock the x when cutting y. Don't make heavy climb cuts without drag on the current axis lock.

ترست بايلوت

منذ 3 أسابيع

منذ أسبوعين