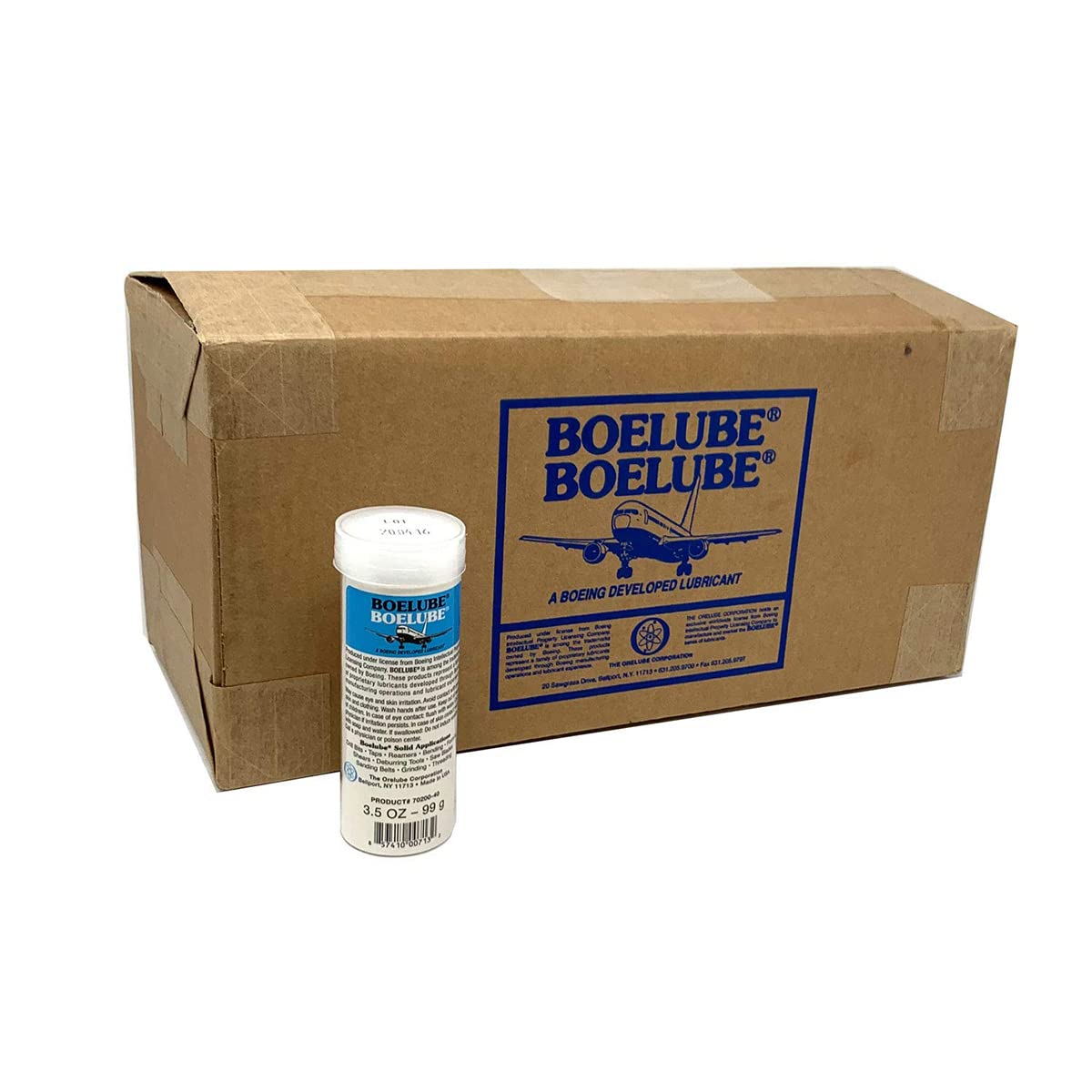

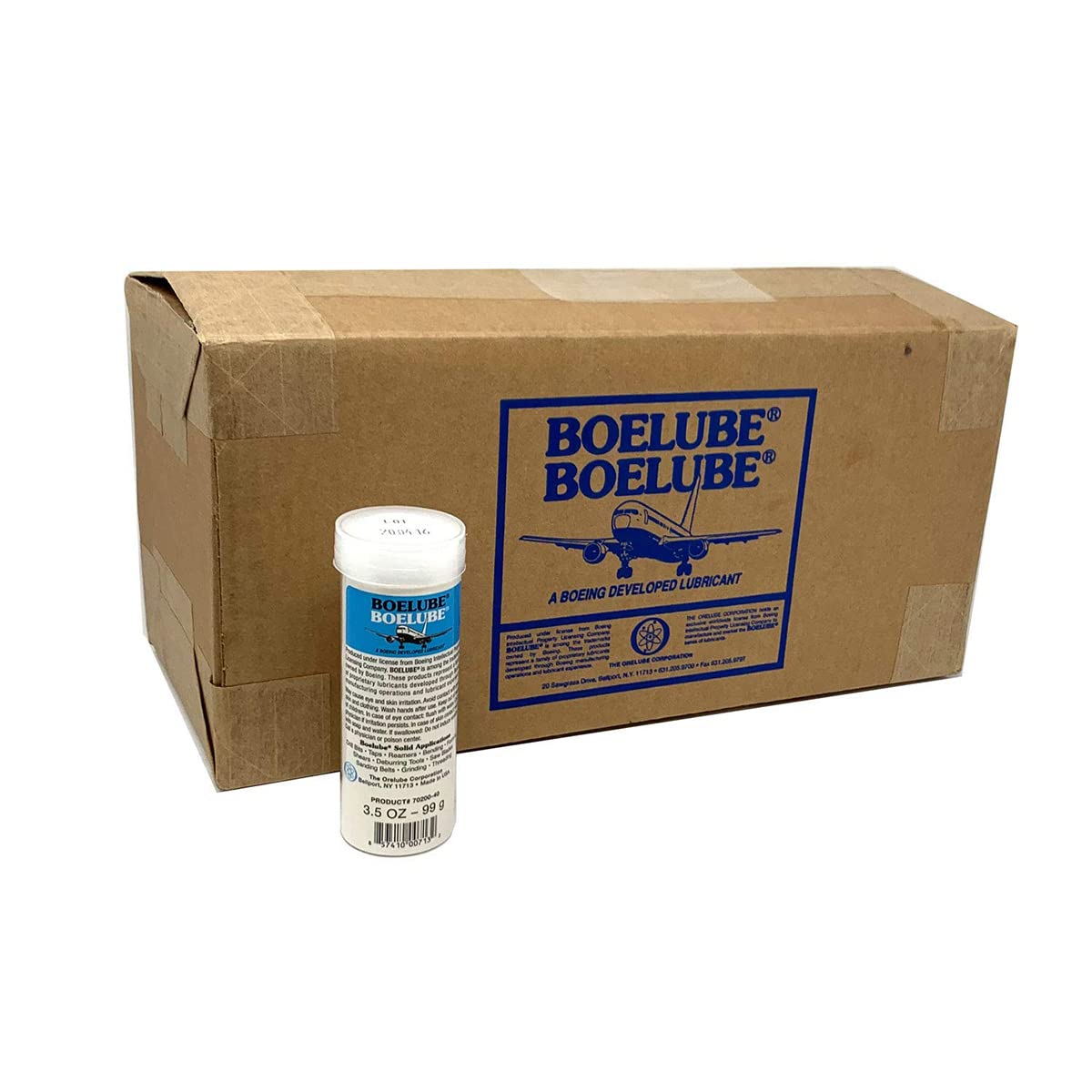

Description

- Exceptional Performance: Boelube push tube provides an excellent means of obtaining maximum stretch area and close tolerance bends by providing superior lubrication that allows the workpiece to attain the desired shape. Comes in a variety of shapes and sizes to accommodate ease of application in drilling, tapping, reaming, abrasive belts, deburring, grinding wheels, band, circular and hand saw blades

- Unique Chemistry: The unique chemistry of Boelube is what provides its superior metalworking lubrication. Manufactured from personal care ingredients, BOELUBE is non-corrosive, non-flammable, chemically stable, and free of halogens, sulfur, phosphorus, silicone, petroleum and paraffin wax

- Superior Lubrication: Boelube 70200 provides best in class lubricity and is ideal for use in aerospace and other manufacturing industries. The lubricant boasts a high film strength and lubricity along with unique polar properties for outstanding performance

- Shelf life: Boelube's superior thermal and oxidation stability provides indefinite shelf life under ambient temperature and conditions. BOELUBE is in most cases compatible with paints and sealants (though it is highly recommended that compatibility be determined before use)

- Flexible usage: BOELUBE Solids are extremely cost effective in single point work such as drilling and reaming. Only a minimal amount is required when drilling through thin material. Typically the BOELUBE solid is applied to the tool before start-up. In a block or tube form, it can be hand held and a drill bit can be touched to the solid before drilling or the solid may be swiped across the surface to be drilled

High Efficiency Machining Lubricant in Solid Form - Boelube 70200 Boelube is a Space Age lubricant that has been developed by The Boeing Company to help reduce friction in cutting components. The advanced solid formula is easy to apply and fights friction at the interface of the cutting edge and the workpiece. The reduction of friction at these surfaces minimises heat generation and concurrent chip weld. Tools retain their cutting edge longer, leading to closer tolerances and prime chip yield. This product does not contain petroleum, sulphur, phosphorus, silicone, paraffin wax and halogen. Also, it is non-flammable, non-corrosive, does not cause irritation when it comes in contact with the skin and is Chemically stable. Apply the solid evenly over the entire workpiece, with both sides being lubricated on larger parts. Specifications: Physical State - Solid Colour - White Melting Range - 90-110°F (32-43°C) Insoluble in water VOC Content - <0.1% (Non-volatile)