🖨️ Flex your prints, not your patience!

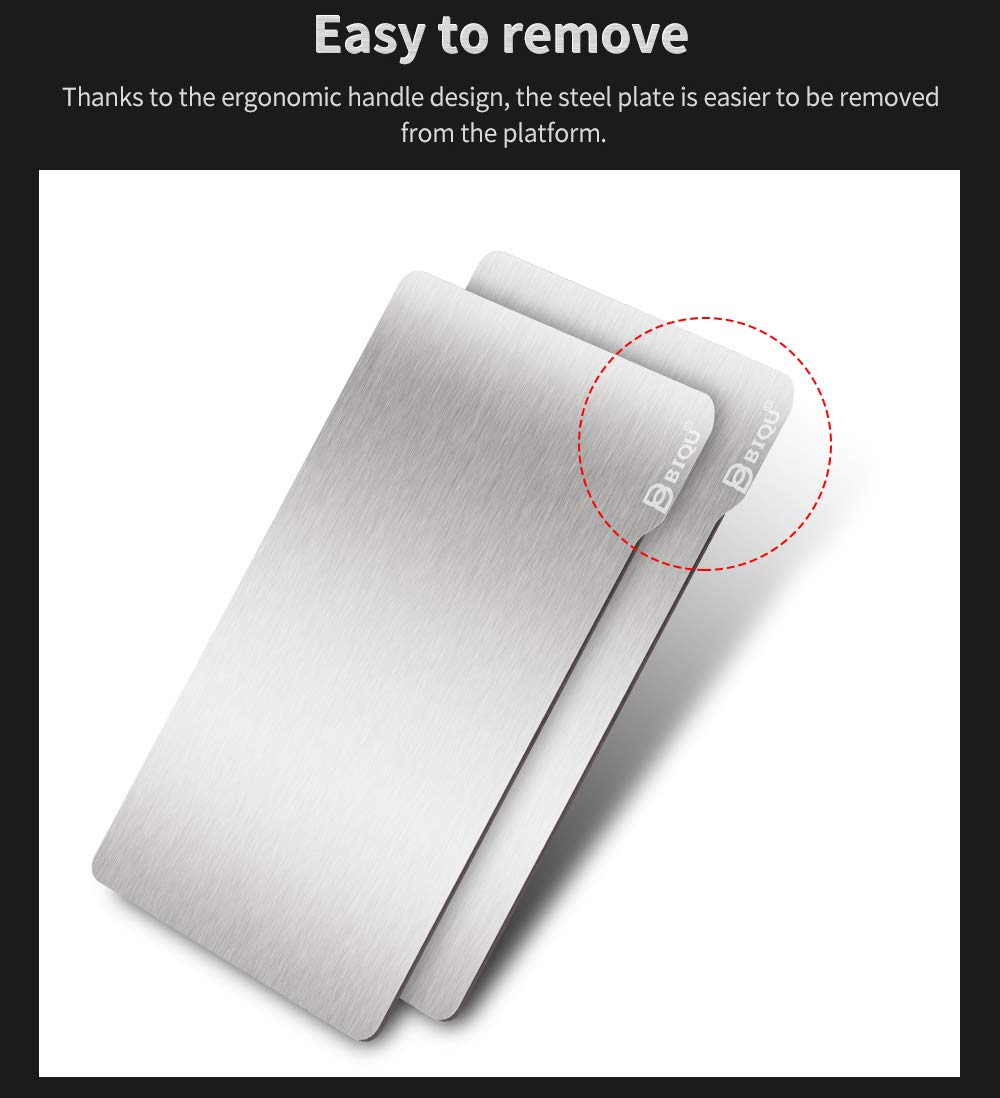

The BIQU Mars Series Resin Build Plate+Magnetic Sheet is a 135x75mm flexible spring steel plate designed for resin 3D printers like Elegoo Mars, Phrozen Sonic Mini 4K, and Wanhao-D7. Featuring a wire-drawn surface for superior adhesion, US-imported spring steel for durability, and a magnetic sheet for secure placement, it enables easy, tool-free print removal with an ergonomic handle—streamlining your resin printing workflow.

R**K

Item is as Described and Works as Intended with the proper prep work!

I bought this product, slightly skeptical as I know magnetic force can be somewhat touchy depending on surface area and adhesion can vary based on surface preparation and the quality of product used. This product came in with 3M, chemical-resistant tape and has more than enough surface area to hold the steel plate to the build plate without any issue.Reviewers who have had the plate fall into the vat or come off in any way must have done something wrong as I cannot see any straight-pull force breaking the plate free from the magnet as I sometime struggle to remove it even when I am trying to and from a corner. The Saturn's bed has a blasted finish so the surface is less than ideal for adhesion, but so long as users follow the instruction below I cannot foresee any future issues.Clean the entire build plate and head with iso. alcohol or acetone to remove any resin residue.If your build plate has any SUBSTANTIAL marks from removing prints, no matter if they are gouges or raised material, those have to be removed so break out some 600g paper, lay it flat on a hard surface, and lap your build plate back to flatness.CLEAN AGAIN with iso. or acetone if you lapped anything to remove both the grit, bed material, any anything that could have been on the paper.Heat the build plate and the magnetic sheet with a blow dryer or some other heat source for 5 to 10 mins. so that it is WARM to the touch through and through (not just for a few seconds and then cools back down).Install your build plate on the machine, upside down and tighten it well.Remove the backing paper on the magnetic sheet from just one end of the sheet, keeping it on the rest so you do not physically touch the adhesive.Lightly start the short edge on the plate and, when you t it where you want it press it down, starting from the middle and working outward.Allow the rest of the magnetic sheet to contact the build plate, removing the backer as you go, and pressing down from the middle out to release any air that may become trapped.When the entire mag sheet is laid out, take a microfiber and press/rub all over it for several minutes as both the sheet and the build plate cool. Most adhesive have a set-up period, so waiting to print for a day would be ideal, but even a few hours would be good to allow things to set-up.I began printing entire plates immediately after install and have no issues. I have also tried to work a corner of the magnetic sheet up (just to see if it would give up easily) and could not do so. This system makes printing easier and better. You may still have to scrape the prints off, but at least you are not scaping your build-plate material and removing the plate allows you to keep the head attached to the machine, saving resin, alcohol life, and reducing cleaning time.Addition considerations:The surface of this plate is rather smooth to allow prints to break free. Before I used mine I blasted it with 120g media. The blasting process creates a surface much like your stock build plate and insures that prints will stick every time without fail, but doing so makes it so you will not be able to easily break your parts off the plate. Blasting CAN warp the plate so if you do it, go slow and do both sides evenly so you do not induce too much heat.I did not try the product with the stock surface so cannot attest to print adhesion.

D**Y

You want this

I was a little hesitant on this build plate as it was priced lower. I read some reviews and decided to try it out. I didn't like printing on the stock surface as I could see some scratches forming where prints were pried off. I hadn't had my resin printer for more than a couple months so I was concerned about adding problems, but I wanted a removeable build surface. It showed up on the doorstep well wrapped in bubble wrap. Removing it from the packaging there were no scratches or blemishes, it looked perfect and flat. The magnet felt very strong. I cleaned everything really well and waited a bit to make sure any residue had flashed off. I was a tiny bit disappointed to see that it was slightly smaller than the build plate on the Qidi Shadow 6, but only a little.I centered the magnet on the build plate as carefully as possible so it laid out flat. The magnet is pretty stiff so it wasn't hard to keep it flat. The spring steel plate is thin enough to be flexible but stiff enough to stay very flat. It looked really good and I was not at all concerned with being able to level it. It does add a few mm of z height. My Shadow 6 has a setting for changing the z stop so I set to leveling and setting the new height. All seemed good so I threw in some resin and hit go on a small test print. When the plate hit bottom it did not stop at the right height and I had to emergency stop it. I decided the end stop blade wasn't reaching far enough into the optic switch to trigger it consistently. I had read about a shim that could be printed for printers with no z stop adjustment but after looking at the blade I was able to put a slight bend in it to move it down about the width added by the new plate.After re-setting the z stop I went through a few tweaks to get the build surface sitting as level as possible. I decided to try printing some new cable chain pieces for my fdm printer upgrade. I packed the plate as full as possible and placed the prints directly on the plate with no supports as a test. They printed beautifully and popped right off the plate with just a little flexing. I made about 10 more sets and then ran a 13 hour print that had failed 5 times before. It printed perfectly. Spend some time getting the leveling perfect and you will love this plate. After around 40 prints I have only had one failure and that was an issue in the file setup. Well worth the money.

J**D

MARVELOUS upgrade for Mars 2 Mono (detailed how-to in review!)

I can't believe how much easier resin printing is with this magnetic flexible build plate! I ordered the 140x85 for my Mars 2 Mono (green), and it works like a champ.Installation was simple, and performance is way beyond what I expected and even hoped for. No more removing the build plate and scraping with a spatula after every print. No more leveling before every print. No more BS. Just printing the way it was meant to be.HOW TO INSTALL FOR MAX RESIN AWESOMENESS:1. Before you do anything - print the Z-stop spacer your machine needs. Go to thingiverse and search "Mars 2 Z stop spacer" or something similar. Print that thing!2. Install the spacer and make sure it does its job. In my case I actually had to stop the build plate from crushing my LCD at the last minute because the spacer I printed wasn't thick enough to stop the plate at the right moment. I ended up having to use the spacer (2.5mm) AND the stock spacer together, with the stock spacer on top of the one I printed. I needed longer screws for this and you probably will too. But after I stacked the spacers the result was MAGICAL.3. With your spacer installed, rub down your build plate with IPA and stick the magnetic thing to the build plate. I set it down and stacked a ton of stuff on top of the build plate for 48 hours to make sure the adhesive was good and stuck.4. After this you're good to go, just slap on the magnetic build plate with the tab towards the back, then re-level your machine and you're golden!BOTTOM LINE:Why are you still reading this? Click buy already.. seriously, you need this thing in your resin printing life. Just as good as the wham bam blah brand! At a fraction of the price.

Trustpilot

5 days ago

1 month ago