🔩 Elevate Your Craftsmanship with Precision!

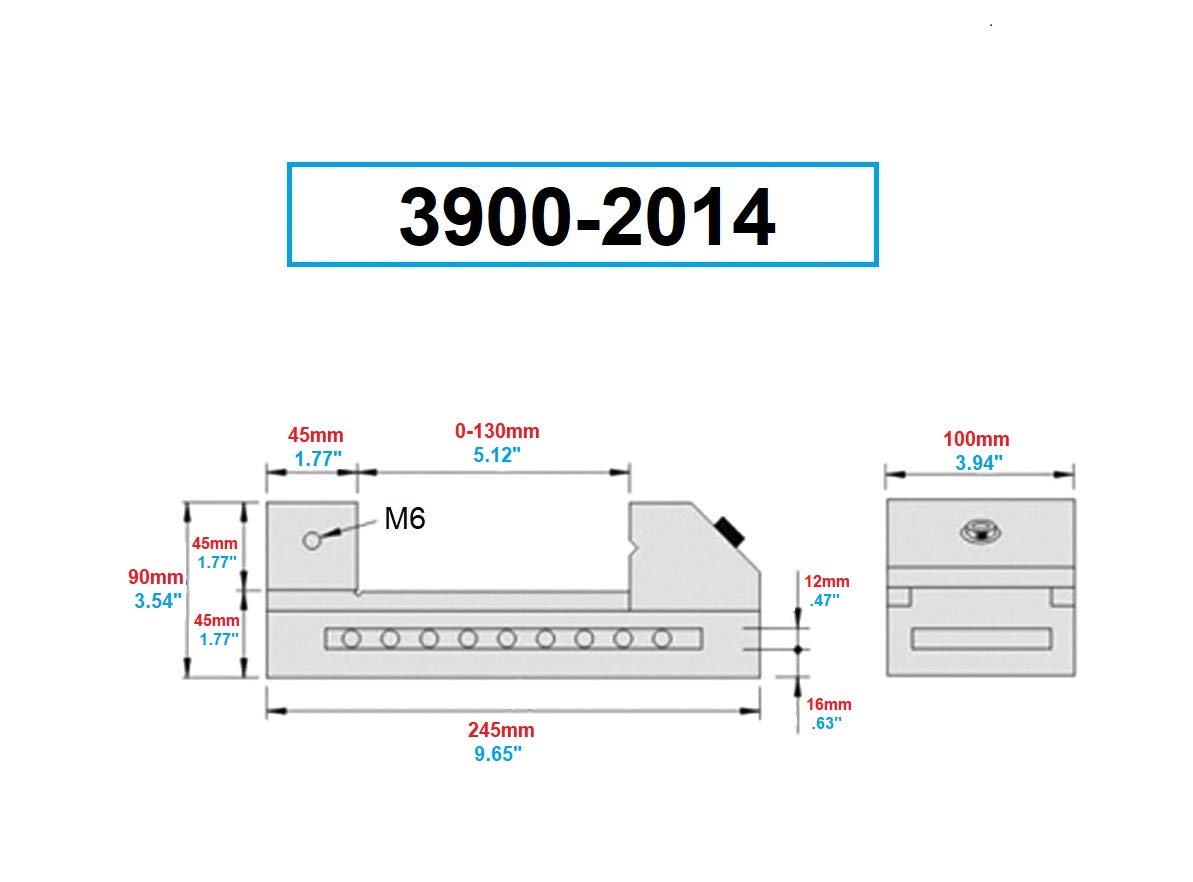

The HHIP3900-2014 4" Ultra Precision Toolmaker's Vise features a 100mm jaw width and is engineered with hardened steel for exceptional durability. With tolerances of .00012" in parallelism and .0002" in squareness, this vise ensures precision in every project. Its innovative design allows for easy jaw operation without unbolting, while the no-rise jaw construction maintains stability and accuracy.

D**Y

Good People. VERY POOR Quality Control.

My wife purchased the 3" vise for me as a gift. This was my first precision machinist's vise, so I had no previous experience as to what to expect of it. I've had two of these now and, as much as I'd like to say otherwise, I can't recommend it due to severe quality control issues.The first one I got had a 0.009" gap on one edge when closed and was missing the set screw that holds the horizontal pin in the bottom end of the clamping nut. Most of the corners had been chamfered but those around the face of the moving jaw weren't. (Those edges shouldn't be heavily chamfered, but these were dead sharp. The edges of the fixed jaw weren't visibly chamfered but the sharpness of the edges had been broken - which I now understand is the way they should be.)I have to say that the folks at HHIP were very responsive and sent me a replacement vise quickly! This is the reason I'm giving the vise 2 stars instead of 1.When the 2nd vise arrived, it had none of the defects that the first one had. Unfortunately, it had a whole different set of problems.My initial plan had been to simply swap the moving jaw from the new one onto the base of the first one but this proved to be impossible, because there was a full 2mm difference in the width of the ways on which the moving jaws slid. (Each moving jaw fitted snugly on the base it came with, but they weren't even close to being interchangeable.)The problems with this 2nd vise were:1. The corners on the face of the moving jaw had been broken correctly, but the corners of the fixed jaw were sharp. ...I fixed this with a little bit of file work. --In doing so, I discovered that the steel was indeed well hardened; not quite as hard as the file teeth, but close - which seems about right to me. To avoid excessive wear to my file, I ended up using a small stone to remove the sharpness.2. The nut that goes on the bottom of the clamping screw was the wrong size for this vise, being quite a bit narrower than the one on the first vise. It fit inside the channel on the underside of the vise body but was very loose, leaving the pin with a lot of unsupported overhang between the edges of the nut and the vise body. This one did have a set screw installed in the nut but the screw was about two turns shy of being tightened down on the pin.3. Comparing the two vises, I discovered that the 6 mm screw holes on the sides of the fixed jaw (which are there to attach any stops or other add-ons you might need) both had problems. The holes on the first vise had been chamfered correctly but the threads were oversized and the screw that I inserted for testing flopped around loosely until I drove it in far enough to bottom out at ~2 cm depth. The holes on the 2nd vise had not been chamfered. The threads were closer to being the right size. My test bold fit with much less slop, but wouldn't go in very far. I found and removed some debris that I think was probably from the grinding process during production. After doing so, the test screw fit correctly. I may decide to chamfer the edges of the screw holes at some point in the future, but am not going to mess with it now since I don't know if I'll ever use them.4. The threads on the clamping screw were damaged. However, the damaged threads were far enough toward the head of the screw that I don't think they'd ever have gone into the clamp nut. Under magnification, I could see that a couple of the threads had been cracked and bent over. I removed the broken pieces easily with a pick. ...On the plus side, the fact that the bad threads had cracked and broken off rather than mashing down and deforming does prove that the bolt was hardened appropriately for use in a machine tool.5. This last problem is almost laughable. The label on the case for the 2nd vise had the right model number (3900-2013), but the wrong description; calling it a 2" vise instead of the 3" (the specs say it's really 73 mm) it actually is.In the end, I was able to make one reasonably good and servicable vise by moving the set screw from the new vise into the correctly sized nut from the first vise, then swapping the good screw & nut into the second one.The people at HHIP were great, but the bottom line is that neither of the two vises I received should have ever left the factory.

M**E

Great Finish, Minor Design Flaw

This vise is very nicely finished and precision ground. Checked mine for parallelism and it is dead on. The fits are nice and tight. The edges could have been broken a bit as they are super sharp out of the box. The screw can easily be backed out too far causing the jaw to disconnect. It can be quite fiddly to try and connect it back together without unmounting the vise. Minor issue but you do need to pay attention when loosening the vise. I could see redesigning that retainer a bit to either avoid the screw backing out too far or to keep the nut lined up better with the vise when it does get backed out too far. I would definitely buy this again.

M**.

Nice vise, poor clamp nut.

Nice little machinist vise. But poor quality on the hardware. The holdown clamp broke, with very little pressure. I made a new one. The vise itself is beautifully made though.

D**M

One major problem, simple fix

Simply, the screw is too long and it’s puts force directly on the retention pin. If you buy this replace the screw before using and maybe remove the set screw and weld the hole.

C**N

High quality, very nice unit, can not beat for the price

This is a very nice vise, no way you can beat it for that price

P**E

Low quality

Jaws not parallel, 0.5mm / 0.02” gap on one side when closed.Covered in grit, screw threads are grinding. Very low quality, returned.

M**C

Perfect...

Really well made...

P**Z

Very good

GOOD

B**N

Better than expected!

Excellent fit and finish. Well oiled from factory, sturdy vise, easy adjustment, with a sturdy plastic storage box.

Trustpilot

1 month ago

1 week ago